The bench is designed for testing the explosion pressure and explosion-proofness of flameproof enclosures “d”.

The bench is used for:

– determination of the explosion pressure (reference pressure) inside the shell at the moment of explosion of the combustible mixture;

– checking the strength of the metal structure of the shell under test;

– test for explosion tightness of the shell – determination of the ability of the sample of the shell under test to prevent the transfer of ignition to the test chamber, when conducting a controlled explosion from a combustible mixture of given gases, inside the shell under test.

The capabilities of the bench meet the requirements for testing in accordance with clause 15.2.2, clause 15.3 of GOST IEC 60079-1-2013 “Explosive atmospheres. Part 1: Equipment with type of protection “flameproof enclosures “d”.

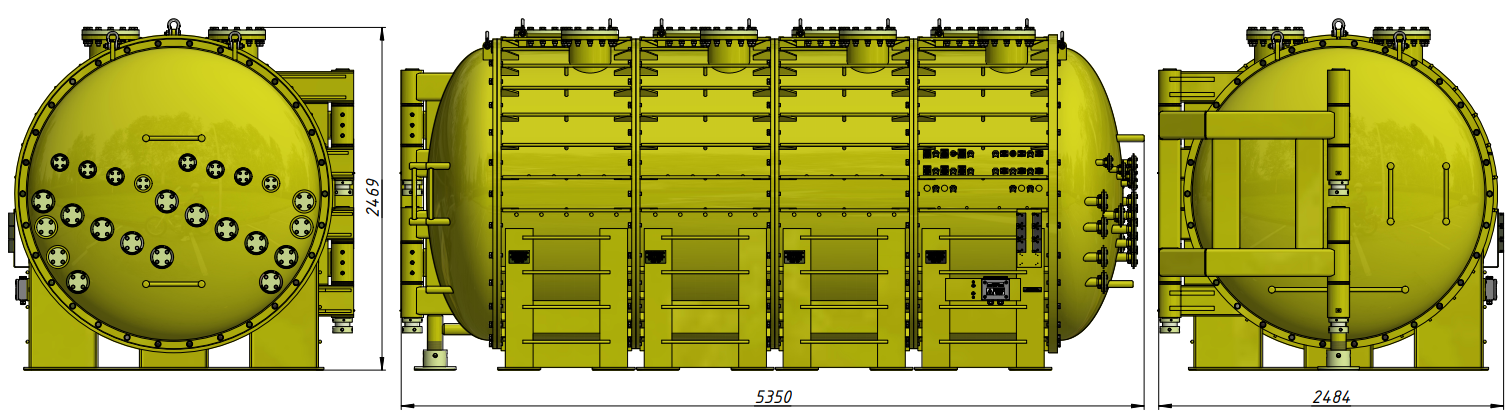

| Parameter name | Parameter value |

|---|---|

| The largest parameters of the test sample, mm: | |

| – width | 2484 |

| – height | 2469 |

| – length when using 2,3,4 sections | 3350, 4350, 5350 |

| Working gases | Methane, propane, ethylene; acetylene, hydrogen, atmospheric air |

| The volume of the working space of the camera when using 2,3,4 sections, m3 | 9,2; 12,6; 16,6 |

| Maximum withstand pressure, MPa | 2 |

| Rated performance of the vacuum pump, m3/ч | 40 |

| Ultimate residual pressure, mbar | 0,1 |

| Vacuum pump motor power, kW | 1,1 |

| Rated frequency of rotation of the pump motor, rpm | 1500 |

| Supply voltage of electromagnetic steel valves two-position flanged with position sensor and coaxial valves |

220 VAC |

| Mass of the chamber shell, kg, calculated | 10600 |

| Pneumatic system weight, kg, no more | 1180 |